Breakthroughs

Four Decades of Multi-market Impact and

Micro-precision Innovation

Breakthroughs

Four Decades of Multi-market Impact and Micro-precision Innovation

Our deep expertise in nano- and micro-structured design has led to award-winning results, high-impact product launches, and long-term supply partnerships with some of the world’s most respected brands.

Our deep expertise in nano- and micro-structured design has led to award-winning results, high-impact product launches, and long-term supply partnerships with some of the world’s most respected brands.

• Scalable Film Widths & Thicknesses Our systems process films between 6″ to 68″ wide, with thicknesses ranging from 12.5 µm to 300 µm, enabling everything from ultra‑thin optical overlays to robust substrate applications.

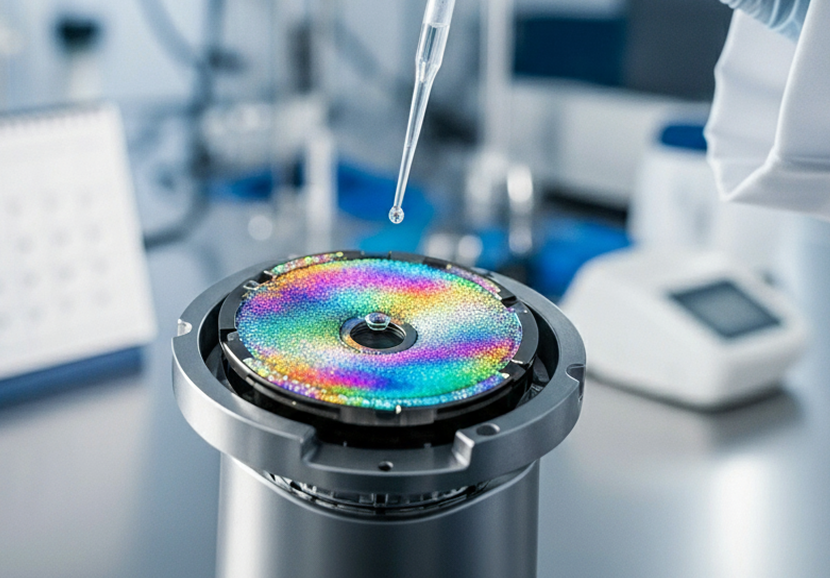

• Hybrid Optical Effects in Packaging & Branding Pushing creative boundaries, WFT combines holographic/diffractive elements with prismatic or Fresnel structures in custom shapes. This enables standout visual depth, movement, and texture in packaging films (liquor, cosmetics, premium products) that both attract attention and resist counterfeit tampering.

• Scalable Film Widths & Thicknesses Our systems process films between 6″ to 68″ wide, with thicknesses ranging from 12.5 µm to 300 µm, enabling everything from ultra‑thin optical overlays to robust substrate applications.

• Hybrid Optical Effects in Packaging & Branding Pushing creative boundaries, WFT combines holographic/diffractive elements with prismatic or Fresnel structures in custom shapes. This enables standout visual depth, movement, and texture in packaging films (liquor, cosmetics, premium products) that both attract attention and resist counterfeit tampering.

Our deep expertise in nano- and micro-structured design has led to award-winning results, high-impact product launches, and long-term supply partnerships with some of the world’s most respected brands.

Our deep expertise in nano- and micro-structured design has led to award-winning results, high-impact product launches, and long-term supply partnerships with some of the world’s most respected brands.

• Holography & High‑security Films For industries needing counterfeiting protection (e.g. security labels, authentication features), WFT's holographic, diffractive, and hybrid films deliver multi‑layered optical security. These incorporate features that are extremely difficult to replicate or forge.

• Lighting & Display Films Advanced diffusers, glare control, prismatic lenses, and freeform micro‑optics for lighting systems and display panels have been engineered to improve light distribution, reduce glare, and enhance visual clarity. WFT's expertise in surface relief structures across broad substrate types allows customized optical behavior for architectural or commercial lighting.

• Holography & High‑security Films For industries needing counterfeiting protection (e.g. security labels, authentication features), WFT's holographic, diffractive, and hybrid films deliver multi‑layered optical security. These incorporate features that are extremely difficult to replicate or forge.

• Lighting & Display Films Advanced diffusers, glare control, prismatic lenses, and freeform micro‑optics for lighting systems and display panels have been engineered to improve light distribution, reduce glare, and enhance visual clarity. WFT's expertise in surface relief structures across broad substrate types allows customized optical behavior for architectural or commercial lighting.

Our solutions aren’t theoretical — they’re embedded in millions of real products and critical systems used worldwide.

Our solutions aren’t theoretical — they’re embedded in millions of real products and critical systems used worldwide.

and critical systems used worldwide.

Packaging

Film for

Specialty

Products

Lighting Film

Implementation

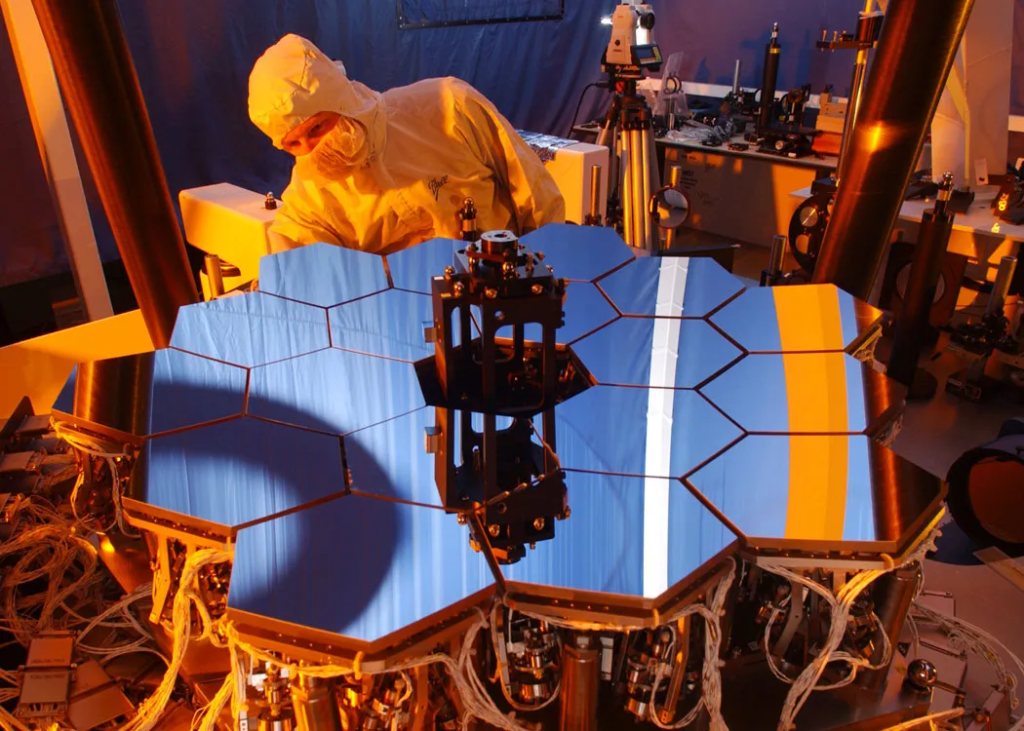

Precision Alignment and Control of Segmented Space Telescope Optics

WaveFront Technology Inc. manufactured the specialized micro-optics and precision optical masters incorporated into the James Webb Space Telescope’s optical system, providing the foundational hardware that enabled accurate fabrication, alignment, and final optical performance. Using advanced diamond-turning techniques, WaveFront Technology Inc. produced the key optical masters used to fabricate the final mirror shells within the Mirror Module Assembly (MMA). Each MMA consists of 24 concentrically nested Wolter-I mirror shells, and the spacecraft contains three identical MMAs.

All diamond-turned optical masters were delivered fully within specification. Their exceptional figure quality significantly reduced downstream polishing and processing time by approximately 50% while simultaneously improving the overall imaging performance of the system. These high-precision masters ensured that each mirror shell met stringent optical tolerances, enabling reliable assembly and alignment of the MMAs.

By delivering flight-qualified micro-optics and ultra-precision optical masters, WaveFront Technology Inc. enabled the conversion of individual mirror elements into fully integrated, high-performance micro-optic components critical to mission success.

and critical systems used worldwide.

Packaging

Film for

Specialty

Products

prismatic structure in non‑standard

shape while keeping high clarity

and print compatibility.

with complex prismatic relief and

holographic pattern, laminated onto

board, die‑cut for shelf, achieving

both aesthetic appeal and

brand‑security.

Lighting Film

Implementation

light evenly in large displays

while maintaining uniform

appearance.

and diffusive films across

substrates with tight thickness

tolerance (12.5‑300 µm) to meet

lighting spec; roll‑to‑roll

manufacturing enabled scalability.

Precision Alignment and Control of Segmented Space Telescope Optics

WaveFront Technology Inc. manufactured the specialized micro-optics and precision optical masters incorporated into the James Webb Space Telescope’s optical system, providing the foundational hardware that enabled accurate fabrication, alignment, and final optical performance. Using advanced diamond-turning techniques, WaveFront Technology Inc. produced the key optical masters used to fabricate the final mirror shells within the Mirror Module Assembly (MMA). Each MMA consists of 24 concentrically nested Wolter-I mirror shells, and the spacecraft contains three identical MMAs.

All diamond-turned optical masters were delivered fully within specification. Their exceptional figure quality significantly reduced downstream polishing and processing time by approximately 50% while simultaneously improving the overall imaging performance of the system. These high-precision masters ensured that each mirror shell met stringent optical tolerances, enabling reliable assembly and alignment of the MMAs.

By delivering flight-qualified micro-optics and ultra-precision optical masters, WaveFront Technology Inc. enabled the conversion of individual mirror elements into fully integrated, high-performance micro-optic components critical to mission success.

An iconic, indulgent Italian brand, La Perla constantly reimagine the changing world around them and in 2017 under the guidance of Master Perfumer Honorine, created a new fragrance to encapsulate the values and sensuality of the brand.

“Exuding beauty and femininity, La Mia Perla is the embodiment of a pearl both in shape and presence and is designed to be worn as a personal emblem. Just as the lustre of a pearl evokes power and intrigue, La Mia Perla tells the story of a woman who finds her own sensuality as it emerges to the surface from within.”

Echoing the precious pearl that is at the heart of the brand they sought out packaging that would support and connect the outer carton with the bottle within and, with our support through creative development and in technical production, have launched a carton that is as recognisable and distinct as the brand.

Philip Morris International has used Fresnel lenses to promote their premium brands since 2011 and in that time, have evolved from the use of simple, small ball lenses to large, deep lenses that cover the entire carton face.

When the Marlboro brand, famed for the male-dominated imagery of their Marlboro Red cowboy advertisements, wanted to reach out to female consumers they developed new products with a different taste, more elegant, slimmer appearance and inevitably, new packaging.

The cartons are slimmer, perhaps more elegant and PMI needed packaging that would reflect these features and appeal to the more discerning, female target audience – using a large lens to appeal would be too obvious, too gaudy and a gentler touch was required.

Retaining the Fresnel lens that is central to the Marlboro brand identity, the graphics rely heavily on the use of opaque white ink to mask off almost half of the front carton face creating a muted, more subtle effect. This is supported by the use of a little matting agent in the attractive pale blue transparent ink that tints the lens and gives the carton its distinctive and uncharacteristic pastel shade.

Holding the inks back from the Marlboro text and subsequently embossing the lettering introduces a further play of the light as it is reflected from the shoulders of the embossed letters in a way that is only possible with a laminated substrate.

Finally, the Marlboro lettering on the base of the carton and the Marlboro chevron was designed to make the most of the branding opportunity of a carton lying horizontally on a table, reflecting the light and creating some movement even in such a small, visible area.

It is a matter of opinion and subjectivity but I believe this carton is equal to many high-end cosmetic packages in the care, thought, and execution of the packing.

The Taittinger team set out to create a carton board sleeve that would enhance the existing rigid presentation box used for their 100% Chardonnay cuvée wine. The challenge was to make a link to the brands current “bubble” identity used across their more standard range whilst enhancing the prestige appearance of the pack.

The graphics were kept simple and combine small Fresnel lenses to simulate the rising bubbles, for which champagne is famous, set into an embossed, achromatic background. The brand owner preferred the softer, matt metallic background over a hard, bright mirror effect as it contrasts nicely with the reflective lenses and silver text whilst its resistance to finger marking gives a superior appearance after handling. Branding is supported through the use of a “pointed lens” in the Teobaldi seal, centred around the horses’ eye, to create movement and depth on the shelf whilst the lettering “Comtes de Champagne” was tooled by hand using a directional grating [a film that reflects light in one direction only] to give the impression of a chiselled, 3D / embossed effect. The carton was finished with a single colour gold wash with additional brand reinforcement through the use of hot foil stamping of the Taittinger name on the sides of the carton.

An area of the laminated sheet which would normally be cut to waste was put to good use and was die cut separately, hot foil stamped and used for the cover of the tasting notes which are included within the inner carton. This helps to reinforce the brand message after the sleeve has been removed and the carton opened, reminding the consumer of the heritage and provenance of the champagne they are about to enjoy.

The brand were extremely pleased with the finished carton and subsequently, by changing the colour of the ink wash from gold to pink, extended the design to encompass their premier Rose champagne.

Skincare has increasingly become a central focus for both leading cosmetic brands and discerning consumers, with individuals willing to invest in creams and serums designed to maintain, enhance, and transform their skin.

Market leader Estée Lauder sought to capitalize on this trend with the launch of their new premium range under the R-Nutriv brand. The challenge was to develop outer packaging that would not only reflect the luxury and efficacy of the products inside but also stand out on the shelf in a highly competitive market.

The R-Nutriv range is an innovative fusion of anti-aging serum and moisturizer, formulated with over 50 high-value ingredients, including precious Black Tourmaline gems, South Sea pearls, refined 24K gold, and proprietary multi-patented Contour Lifting Technologies. Translating this level of sophistication into packaging required both technical and creative excellence.

Wavefront introduced a registered Fresnel lens to the face of the carton, eliminating the need for traditional labeling while creating an eye-catching effect that drew attention to the product. Additionally, the strategic use of a heavy, opaque varnish added a subtle shimmer and dynamic movement, reflecting the luxurious, transformative qualities of the R-Nutriv products.

The result was a packaging solution that communicated premium quality, innovation, and elegance, reinforcing Estée Lauder’s position as a market leader in luxury skincare while delivering a visually compelling experience for the consumer.

After the remarkable success of Christmas 2016, when Moët & Chandon first experimented with Fresnel-enhanced packaging, the iconic Champagne house decided to take their innovation even further. For the following festive season in 2017, they once again partnered with Wavefront, challenging the team to design a packaging concept that would not only reflect the prestige of the brand but also achieve maximum impact on duty-free shelves around the world.

Wavefront’s creative solution was a sophisticated radial pattern, carefully crafted by combining multiple layered effects. This unique design delivered a striking sense of movement, depth, and brilliance, ensuring that the carton instantly caught the eye of passing travelers. The interplay of light across the Fresnel features brought the packaging to life, reinforcing Moët & Chandon’s reputation for elegance, celebration, and innovation.

The result was a premium presentation that elevated the brand’s holiday presence, turning a simple carton into a captivating visual experience and further cementing Moët & Chandon’s position as a global leader in luxury Champagne.

“MARTINO by Martino Cartier’s proprietary elixir Jewels of the Nile delivers the ancient benefits of Myrrh, Papyrus Milk, Blue Nile Honey and Rose Attar into expertly crafted modern day formulas infused with biotin and caffeine to promote healthy and vibrant hair.”

Mr Cartier has used some rare and exotic ingredients to create this range of special, highly prized hair treatments and in looking for an appropriate finish and decorative technique for the tube that does justice to the content within, has chosen Wavefront to provide the visual appeal.

The use of gold and black inks only enhances further the perception of quality and luxury delivered by this brand and reminds the consumer at every use, why they bought this premium product.

This tube marks a breakthrough in in-mould labeling and indicates just how versatile and adaptable Wavefront Fresnel films really are whilst demonstrating the potential for continuous designs when used in the right application.

Transforming industries through innovative optical solutions across diverse market sectors

Transforming industries through innovative optical solutions across diverse market sectors

Brand Identity

Security, and decorative appeal.

• Diffractive Films – Create shimmering, color-shifting appearances.

• Hybrid Films (Holography + Fresnel) – Enhance package visibility with depth and motion.

• Microstructured Decorative Films – Add tactile and visual branding elements.

• Ultra-thin TMD Films – Ideal for compact lighting setups.

• Fresnel Lens Films – Focus or redirect light in directional applications.

• Prismatic / Faceted Films – Collimate or distribute light effectively.

• TMD® Films – Manage viewing angles and brightness uniformity.

• Ultra-Thin Diffuser Films – Support ultra-slim display designs.

• Laminated Films on Rigid Substrates – Used in durable, protective display covers.

• Diffractive Elements – Provide unique, hard-to-replicate visual patterns.

• Microstructured Security Graphics – Custom-designed structures for covert verification.

• Anti-glare Films – For cockpit displays or instrument panels.

• Laminated Optical Films – Bonded to rigid substrates for structural integrity.

• TMD® Films – Used in specialized lighting or display modules within aircraft interiors

• Diffractive Films – Create shimmering, color-shifting appearances.

• Hybrid Films (Holography + Fresnel) – Enhance package visibility with depth and motion.

• Microstructured Decorative Films – Add tactile and visual branding elements.

• Ultra-thin TMD Films – Ideal for compact lighting setups.

• Fresnel Lens Films – Focus or redirect light in directional applications.

• Prismatic / Faceted Films – Collimate or distribute light effectively.

• TMD® Films – Manage viewing angles and brightness uniformity.

• Ultra-Thin Diffuser Films – Support ultra-slim display designs.

• Laminated Films on Rigid Substrates – Used in durable, protective display covers.

• Diffractive Elements – Provide unique, hard-to-replicate visual patterns.

• Microstructured Security Graphics – Custom-designed structures for covert verification.

• Anti-glare Films – For cockpit displays or instrument panels.

• Laminated Optical Films – Bonded to rigid substrates for structural integrity.

• TMD® Films – Used in specialized lighting or display modules within aircraft interiors

Taittinger Award

Awards

Honoring Innovation, Excellence, and Industry Leadership

At WaveFront Technology, our commitment to advancing optical engineering and delivering groundbreaking solutions has earned us numerous prestigious awards and industry accolades. These recognitions underscore our expertise, innovative spirit, and consistent delivery of high-impact optical components across multiple sectors.

Recognized for excellence in carton design and sustainability, this award celebrates WaveFront's innovative use of Fresnel lenses and microstructured films in luxury packaging for Taittinger Champagne. Our solutions enhanced both the visual appeal and tactile experience, pushing the boundaries of what packaging can achieve in a competitive market.

Awards & Certification

Honoring Innovation, Excellence, and Industry Leadership

At WaveFront Technology, our commitment to advancing optical engineering and delivering groundbreaking solutions has earned us numerous prestigious awards and industry accolades. These recognitions underscore our expertise, innovative spirit, and consistent delivery of high-impact optical components across multiple sectors.

Taittinger Award (2012)

Years of Combined Experience

In engineering, optics, and manufacturing

Years Experience

Continuous innovation

since 1986

Multi-Industry

Impact

Serving Aerospace, Lighting, Security,

Packaging, and Display markets

From Concept to Cutting Edge

We Control Light®

innovation, transforming industries and setting new standards for precision and excellence.

We Control Light®

This isn’t just our tagline, it’s our promise. For over four decades, we’ve been at the forefront of optical

innovation, transforming industries and setting new standards for precision and excellence.